The selection of a drill bit is crucial to achieving optimal drilling performance. This selection is influenced by various factors, including the hardness of the soil, its abrasiveness, the drilling method, the diameter of the borehole, and its length. The type of drill bit and its corresponding borehole diameter is also dependent on the specific application, such as rock bolting, soil nailing, or micropiling.

In the self-drilling anchor system, minimizing the impact on surrounding soil and rock is a key consideration. By optimizing drilling speed and energy application, these systems maintain efficiency across various geotechnical conditions. Self-drilling anchor cross drill bits and self-drilling anchor arch drill bits are commonly used for mixed fill-type soils, such as clay, loam, soft shale, or silty clay, effectively cutting and scraping through these formations. For harder geological formations, the use of self-drilling anchor button drill bits with tungsten carbide inserts, self-drilling anchor cross drill bits, and self-drilling anchor three-cutter drill bits is recommended. These bits effectively utilize impact energy to penetrate dense and abrasive materials.

The selection of the appropriate drill bit type is crucial for ensuring efficient installation, durability, and compatibility with diverse ground conditions, making it a vital component of the self-drilling anchor system.

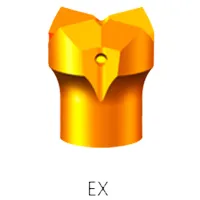

EX: Fully machined cast or forged all-steel cross drill bits, treated with quenching and hardening processes. These drill bits are primarily used for construction in soft rock formations and are a common choice for self-drilling anchor systems.

EXX: Cross drill bits with tungsten carbide inserts at the tip. These are designed for use in both soft rock and medium-hard rock conditions, offering enhanced durability and cutting performance.

ES: Fully machined cast or forged all-steel button drill bits. These bits are primarily used for medium-depth anchoring in soft rock and fractured medium-hard rock formations.

ESS: Button drill bits with tungsten carbide teeth embedded at the tip. Thanks to the tungsten carbide inserts, these drill bits are ideal for construction in medium-hard rock formations. They are characterized by fast penetration speed, smooth drilling performance, and reduced risk of jamming.

EC: Asymmetrical all-steel arch drill bits formed through forging. These bits are designed for unconsolidated soil and small stones, offering faster penetration in soft rock formations.

ECC: Arch drill bits with tungsten carbide inserts embedded in the tip. These are suitable for anchoring in medium-hard fractured rock formations, providing durability and efficiency in challenging conditions.

EY: All-steel three-cutter drill bits, forged or cast, used for anchoring in loose soil and rock formations.

EYY: Three-cutter self-drilling anchor drill bits with tungsten carbide inserts. These are ideal for anchoring in medium-hard rock formations, providing enhanced cutting performance and durability.

| Bit Selection | |

| EX | All-steel cross bit designed for loose to medium-dense ground conditions. |

| ES | Hardened button bit ideal for weakly cemented soils, sands, and fractured rock layers. |

| EW | Specialized clay bit for soft clay and soil formations. |

| EC | Forged arch bit suitable for loose to dense soil and sand formations. |

| EY | Durable three-cutter bit for weakly cemented soils and fractured rock formations. |

| EXX | TC cross bit engineered for medium to strong fractured rock conditions. |

| ESS | TC button bit optimized for strong fractured rock formations. |

| ECC | TC arch bit crafted for medium fractured rock layers. |

| EYY | TC three-cutter bit designed for medium fractured rock formations. |

| Bit Matrix | ||||||||||||||

| Dia. | 42 | 51 | 76 | 90 | 100 | 115 | 130 | 150 | 175 | 220 | 250 | 280 | 300 | 350 |

| R25 | ● | ● | ||||||||||||

| R32 | ● | ● | ● | ● | ||||||||||

| R38 | ● | ● | ● | ● | ● | |||||||||

| R51 | ● | ● | ● | ● | ● | ● | ||||||||

| T76 | ● | ● | ● | ● | ● | |||||||||

| T30 | ● | ● | ||||||||||||

| T40 | ● | ● | ● | ● | ||||||||||

| T52 | ● | ● | ● | ● | ● | ● | ||||||||

| T73 | ● | ● | ● | ● | ||||||||||

| T103 | ● | ● | ● | ● | ● | ● | ||||||||

| Thread standard | ISO 10208 / ISO 1720/ Other international standards | |||||||||||||

| Thread direction | Left hand / Right hand | |||||||||||||

| Hardness | HRA87-HRA90 for TC bits, HRC 48-HRC 55 for all steel bits. | |||||||||||||